Industrialization is possible not just with machines, but through a combination of vision, resilience, and labor. The unsung heroes of Turkey's growth story have created significant revolutions in small workshops, leaving their mark on today's economy. Ali Ateş's story is one of these heroics. It begins with his apprenticeship and transitions into a groundbreaking journey in engineering... The value he has built should be seen not just as a factory, but as a culture, a vision, and a valuable legacy left to future generations. It now falls upon us to take ownership of this legacy, to multiply it, and to pass it on strengthened to the next generation.

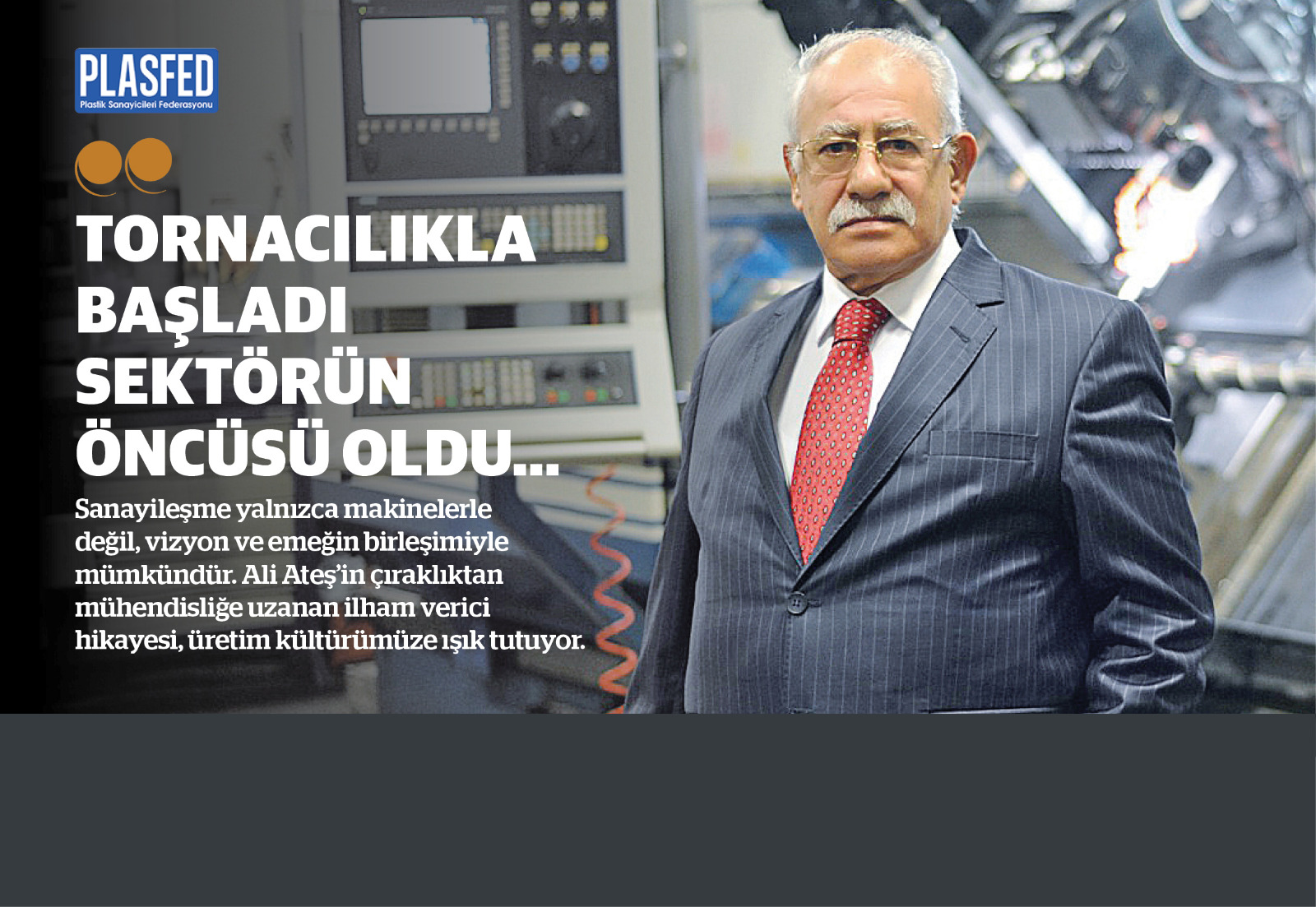

Born in Dereboğazı village in Elazığ, Ali Ateş became one of Turkey's leading names in the plastic machinery sector, starting his career as a lathe operator. His success story, which began at the age of 12 when he was introduced to the industry, is the greatest testament to what can be achieved when determination and vision come together...

Ali Ateş was born in 1951 in Dereboğazı village, Elazığ. His father, who made a living as a farmer, placed 12-year-old Ali in a small lathe workshop in Elazığ after primary school. This was a time when not everyone had the chance to be an apprentice and no one earned a salary from apprenticeships. Ali's father paid him out of his own pocket just to encourage him to learn a craft.

Ali Ateş continued working in this workshop from 1963 to 1968. In 1968, he wanted to work as a lathe operator in the construction of the Keban Dam. He applied but was not hired due to his young age. Later, he started working as a lathe operator on the construction of the Gürüşgür Bridge between Elazığ and Palu.

After a period of unemployment following the bridge construction, Ali’s father came to Elazığ and asked him why he wasn't working. Although Ali said, "Dad, there are no jobs," his father was quite upset with him. As a result, 16-year-old Ali took 68 lira from his 100 lira pocket money, bought a bus ticket, and moved to Istanbul. In Istanbul, he went to a friend he had previously worked with and applied to the then newly established İnci Plastic Jüt A.Ş. as a lathe operator, where he was accepted. Starting to work at the İnci Plastic factory in Topkapı Gümüşsuyu, Ali used construction boards to create a bed and began living at the factory. His boss Taki Vatandost saw that Ali was a good craftsman and offered him a salary of 175 lira. After receiving his first week’s pay, Ali bought a bed and a quilt from Tahtakale and continued to stay at the factory.

AT 23, HE ESTABLISHED HIS OWN WORKSHOP

After going through intense apprenticeship and skilled labor, Ateş began his entrepreneurial journey by establishing his own workshop at just 23 years old in 1974. Initially starting production by repairing screws and barrels for plastic machines, he closely observed the needs of the industry and laid out his vision. Over time, he began producing specialized screws and barrels for the plastic sector, quickly analyzing significant gaps in the industry and seizing opportunities to fill these voids with local production.

SIGNING MANY FIRSTS IN THE INDUSTRY

The 1980s were the years when Almak Ateş Machinery experienced significant growth. The 60 square meter workshop in Topkapı Gümüşsuyu was combined with a neighboring workshop, increasing the size to 120 square meters. With a rising demand for screws and barrels, Ali Ateş decided to expand in this field. "When we started producing screws and barrels, the only company doing this in Turkey was Hasmak Makine's Hasan Manav. To take a step forward with the flag, I bought Turkey's first deep drilling machine in 1982. In 1983, I produced Turkey's first scrap packaging machine," he stated.

Ali Ateş mentioned that a customer requested a machine to compress and package scrap materials to send to melting furnaces, stating, "I took that job for 2 million 450 thousand at that time’s money. I had 1.5 million lira, and it was gone, but I didn’t give up. We were determined and after 5-6 months, customers started to come. Initially, we could only complete one press machine every four months, but by working double shifts, we managed to prepare four press machines a month."

Later, with the money earned from press machines, a 900-square-meter land was purchased next to the Kale Lock factory in Güngören in 1984. Construction began in 1985 and was completed in 1988, allowing the company to continue operations in 700 square meters of closed area in this new workshop.

By 1988, the press machine business started to slow down, prompting a shift in focus toward screw and barrel production.

FAMILY TRADITION CONTINUED

Today, Ali Ateş continues working at Altech/Almak Ateş Machinery, which he founded, alongside his two sons, Mustafa and Emrah Ateş, imparting the knowledge he has gained to the younger generation.

Mustafa Ateş, born in 1976, started working at the firm after graduating from Marmara University’s Public Relations Department. Ali Ateş's other son, Emrah Ateş, joined the company in 2004 after graduating from Kocaeli University’s Mechanical Engineering Department. Emphasizing that his children were always involved in work from a young age, Ali Ateş said, "They got to know me after the age of 10. Since I worked double shifts, they rarely saw me at home. I didn’t allow them much free time to play while in school. I also paid close attention to who their friends were; the people one associates with in life are important. Shortly after Mustafa started working at the factory, he attended a fair in Russia with one of our masters. All travel and accommodation expenses were covered. I put 5 thousand dollars in his pocket as fun money for the four-day fair. They returned after four days, and Mustafa put 4,200 dollars on my desk. Two people spent only 800 dollars. This behavior earned me great confidence, and I said, ‘If you had spent all that money and returned, I wouldn’t have entrusted the business to you, but now this flag is yours!’ Since that day, my children have managed the business. Of course, I’m consulted when decisions are made. I didn’t work hard to buy my children a plot or an apartment. I did everything I could to provide them with the best education. Someone without a good education tends to waste the resources at hand. However, a well-educated person can easily acquire both their land and shop with their mind and skills, if they want,” he expressed.

AT THE FOREFRONT OF A FACTORY: A TURNING POINT IN INDUSTRY

1998 marked a turning point in Ali Ateş’s career and in Turkish plastic industry. By establishing Turkey’s first integrated screw and barrel production facility, Ateş filled a significant gap in the industry, paving the way for a production approach based not only on parts manufacture, but also engineering, design, and R&D.

Almak Ateş Machinery launched the first heat treatment oven in 1998, achieving the status of being Turkey's first and only integrated screw and barrel plant. In order to continue with machinery manufacturing, the Altech company was established in 2000. Emrah Ateş took over the management of Altech, which specializes in plastic recycling machines, in 2004.

As the workshop in Güngören began to become insufficient, a search for a new location commenced. Consequently, land in Esenyurt, which is now the company’s headquarters, was purchased and construction began. The construction was completed in 2015 and the new factory was opened. While Almak Ateş Machinery continues screw and barrel manufacturing in 2,700 square meters on the lower floor of this new 10,000 square meter factory, the upper floors continue Altech machinery manufacturing. Stating that both companies' capacities have increased after the new factory's opening, Ali Ateş remarked, "Apart from our two companies, we have also purchased a 6,000 square meter place in Hannover, Germany, and determined a roadmap to start production in Europe. There, we established a company called Remaplast GmbH that sells plastic equipment. We also set up Altech's showroom in Germany, preparing an environment for our European customers to test machines without coming to Turkey. Currently, our top priority at both Almak Ateş Machinery and Altech is R&D efforts. As a result of these efforts, we have produced products for the first time in our country," he stated.

LOCAL INNOVATION WITH BIMETALLIC COATING

In 2020, Ali Ateş took another pioneering step. He became the first local company to produce bimetallic coated screws and barrels in Turkey. This special production method not only significantly extended the lifespan of machine parts but also elevated the quality standards within the industry.

Ateş explained that they transitioned to producing bimetallic coated barrels in extruders and injection molds, stating that they achieved significant advancements regarding prolonged lifespan and wear resistance, up to four times. He also noted the development of an automatic laser filter system. Thanks to automatic laser filters, produced for the first time in Turkey, the granules coming from Altech's recycling extruders have high performance levels without frequent filter replacements. Highlighting the advantages of the Mikrofilt Laser Filter Systems with a very favorable price-performance ratio that revolutionized the recycling industry, Ateş stated, "The foundation of these successes lies in the dynamic structure of our R&D and innovation team. We strive to manage all our staff like a football team. That is, we do everything we can for a good team play. We've set this as a corporate policy."

Translated by Artificial Intelligence